Non-product Zone

Motors for the non-product zone

In this zone, contact with food is excluded (therefore: non-product zone). Here, in contrast to the Hygienic Design Zone and the Spray Zone, there is no risk of food contamination. Of course, these motors can also be adapted to individual requirements - for example, to a specific application site or cleaning schedule. Here, too, the principle of avoiding sources of contamination applies.

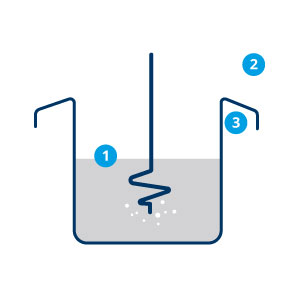

Overview: zoning in the beverage and food industry

| ❙ 1. Hygienic Design Zone: (process-integrated) | Food is in contact with the drives and the components |

|---|---|

| ❙ 2. Spray zone: (near the process) | Drops/splashes of food can get back into the manufacturing process and cause contamination. |

| ❙ 3. Non-product Zone: | No food contact possible |

Non-product Zone

| Demand on hygienic design | Low |

|---|---|

| Material | Aluminium and steel |

| Surface | Special coatings |

| Protection class | IP65 |

| Cleaning | Dry or damp cleaning |

| Achievement of EHEDG criteria | No |

Download Catalog

Motors and Gearboxes for Food, Pharmaceutical and Process Engineering (ID: 221170 V11/2016)

High demands have always been placed on the production of foodstuffs and pharmaceutical products in order to guarantee reliable consumer protection. These requirements must also be met by all production components used.

![[Translate to English:] GEORGII KOBOLD](/fileadmin/user_upload/logo.jpg)

![[Translate to English:] Motoren und Getriebe für Food, Pharma und Verfahrenstechnik (ID: 221170 V11/2016) [Translate to English:] Motoren und Getriebe für Food, Pharma und Verfahrenstechnik (ID: 221170 V11/2016)](/fileadmin/_processed_/a/f/csm_georgii-kobold_katalog_antriebe_grau_f2ca307440.jpg)